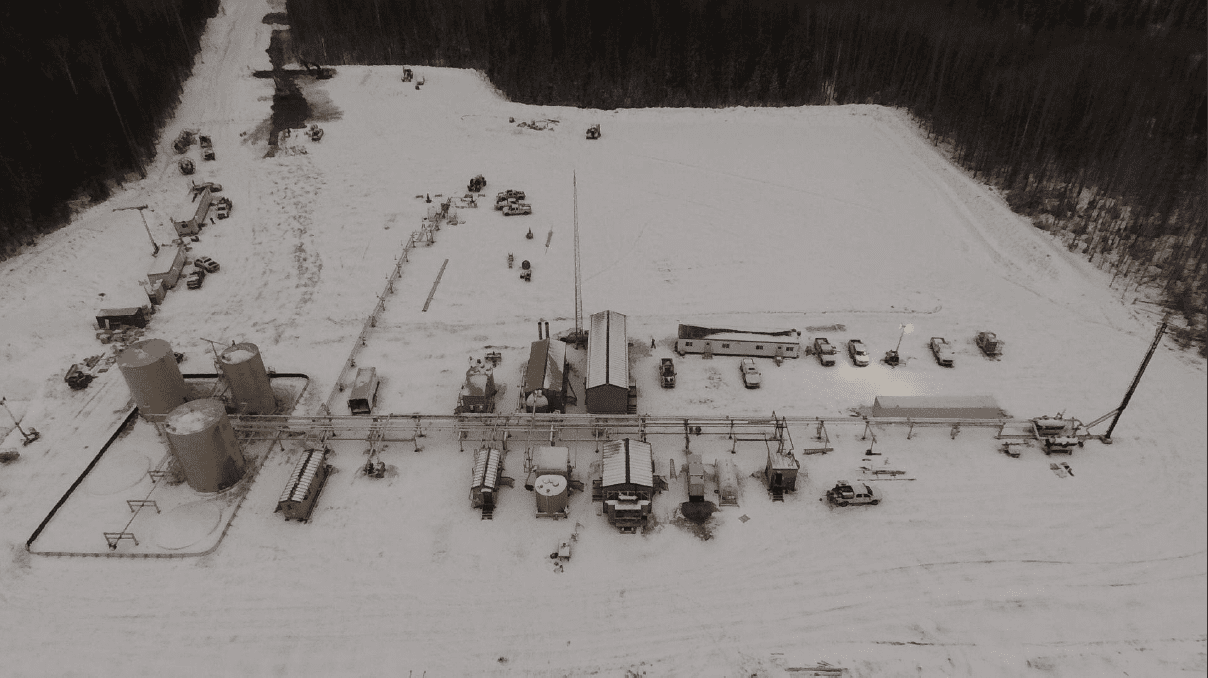

Oil Batteries

Tundra Engineering knows oil. Tundra has worked with all grades of oil, heavy to light, sour to sweet, low GOR to high GOR, SAGD to CHOPS, Conventional to Unconventional (shale). We have incorporated all types of artificial lift from Pump Jacks, Progressive Cavity, Jet Pumps, ESPs and Gas Lift. We work with all upstream oil processes including separation, oil treaters, tank treating and all other accessories, and routinely support project development through detailed engineering and Application for Expenditure preparation. Project types include all different types of upstream and midstream projects:

- Greenfield, Brownfield or MOC (Management of Change) Projects

- Treators for oil treating

- Tank treating

- Oil Sweetening

- Blending

- Solution gas conservation

What is oil treating and how is it done?

Upstream oilfields collect oil into central batteries for treating, metering and sales. This oil may be pipelined in or brought in by trucks. Oil treating is removing the water and solution gas from the oil so it can be safely trucked away or pipelined away. In some cases oil needs to have H2S removed (sweetening) for safety reasons or to meet the sales spec.

Treating can be accomplished using tanks in series (tank treating) or using specialized vessels but the principle is the same: heat the fluid at low pressure to allow separation of the gas from the emulsion AND encourage the separation of the emulsion into a water outlet stream and an oil outlet stream.

The lighter the oil (>25 API) the more likely tank treating can work but the more important safely dealing with the liberated gas becomes. In contrast, the heavier the oil (<25 API) the more likely a specialized treater is required with additional features such as an electrostatic bed etc. is required. Heavy oil can require very large treaters and are very specialized.

Most sales-quality crude in tanks is required to be 0.5% BS&W or less by volume, with many contracts targeting 0.2–1.0% depending on crude type, pipeline, and buyer.

Typical numbers you’ll see

- Pipeline / terminal crude: Common spec is ≤0.5% sediment + water for “on‑spec” crude into most pipeline systems.

- Light and intermediate crudes: Shipping specs are often written as ≤1.0% BS&W max, but actual traded cargoes and pipeline receipts usually run lower (≤0.5%).

- Heavy crudes and off‑spec streams: Can be allowed higher BS&W (up to 2–3%) in special contracts, but that is explicitly treated as off‑spec or discounted crude.

How it’s enforced

- BS&W is typically measured by centrifuge (ASTM D4007 and related methods) or LACT units at custody transfer points, and the spec is written directly into the sales or pipeline tariff.