EPCM Services for Pump Solutions and Implementations

Pump Solutions and Implementations

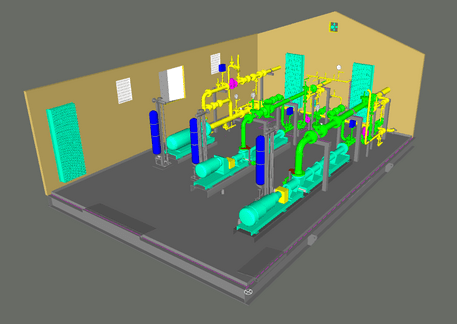

Tundra Engineering provides practical support across the major pump categories used in oil and gas, municipal, industrial, and utility services, helping clients select fit-for-purpose equipment for both new installations and retrofit projects.

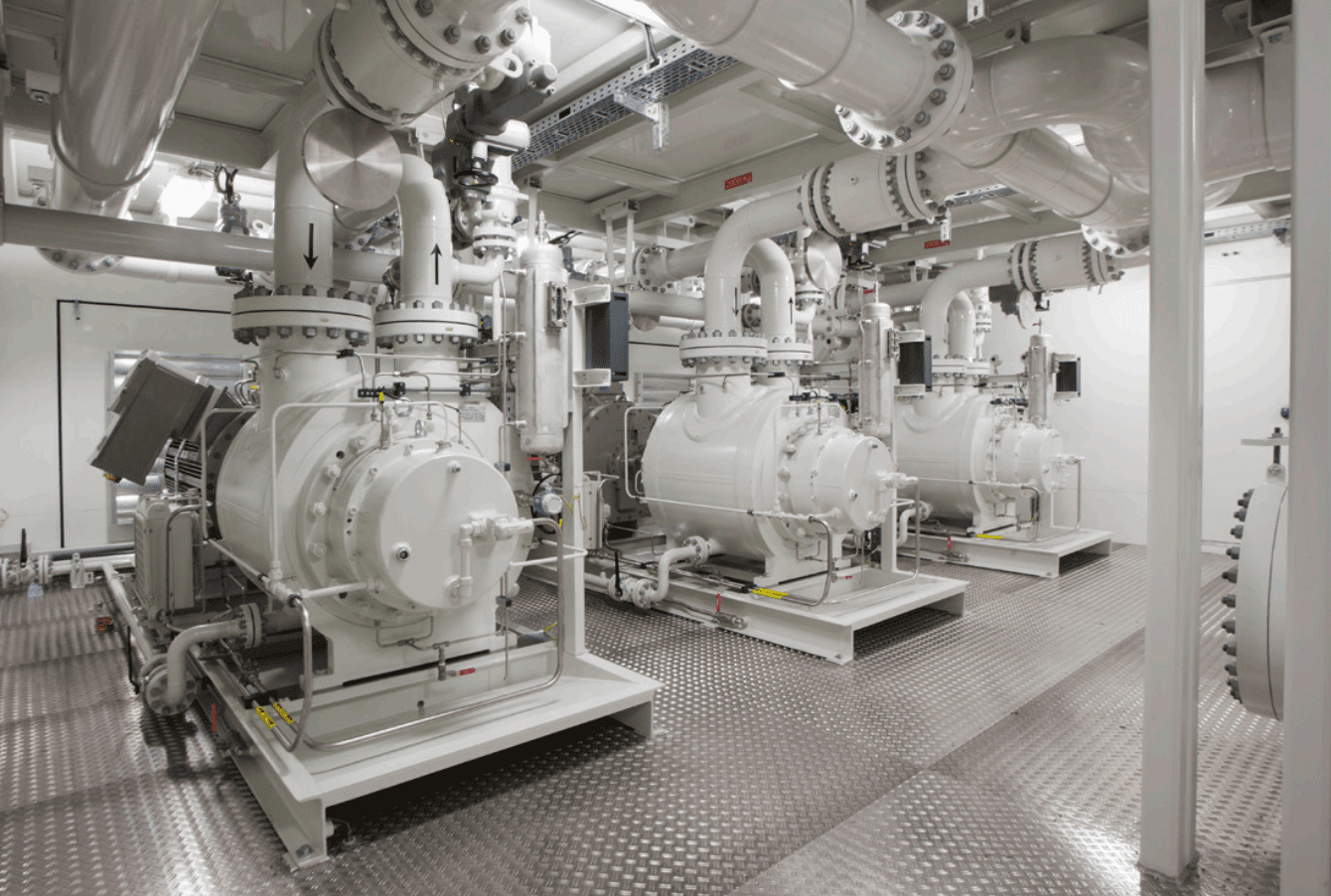

Screw pumps are available in single-phase and multiphase configurations, covering the full range from food-grade hygienic service to heavy-duty slurry and multiphase production handling. They provide smooth, low-pulsation flow for shear-sensitive, viscous, or solids-bearing fluids in applications such as process transfer, loading, and multiphase gathering.

Centrifugal pumps are typically applied where higher flow and moderate head are required, including produced water transfer, cooling and service water, pipeline boosting, and general process circulation. We assist with selecting single-stage, multistage, horizontal, and vertical configurations to match process conditions and site constraints.

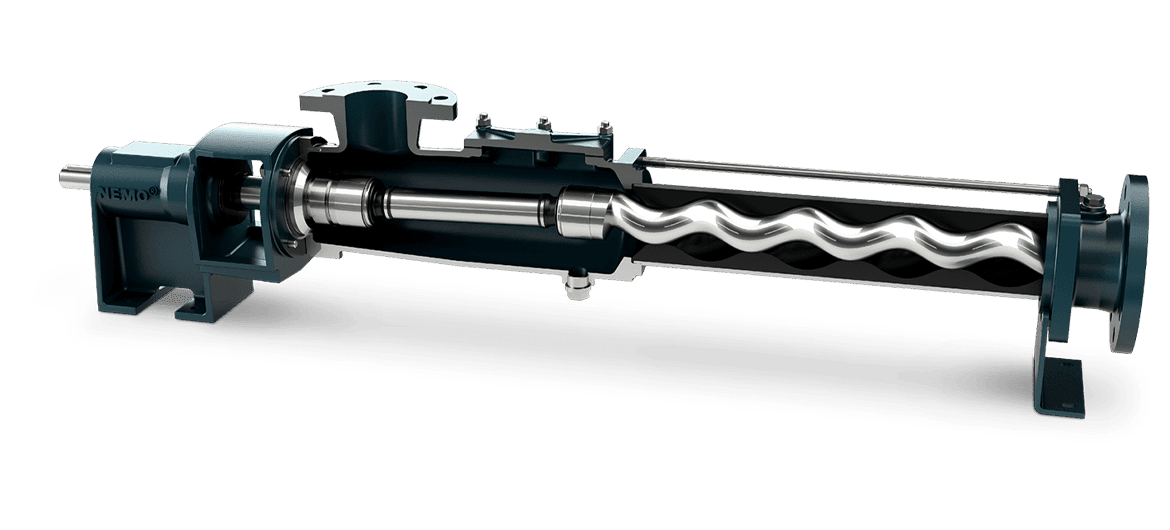

Positive displacement pumps are used where steady, accurate flow is important, high pressure is required, or fluids are viscous or shear-sensitive. This includes reciprocating plunger and piston pumps, as well as screw, gear, and diaphragm designs, applied in chemical and water injection, metering, lube oil systems, polymer transfer, and heavy oil or specialty dosing services.

Progressive cavity pumps are well suited for multiphase, solids-laden, or highly viscous fluids where gentle handling and consistent flow are critical. Also known as a Progressing Cavity or a Screw Pump. These pumps are commonly applied for heavy oil, emulsions, slurries, and wastewater or sludge transfer duties.

Horizontal high-pressure multistage (HPS) pumps are used where compact, reliable, high-head fluid transfer is needed. These units are well suited for pipeline boosting, waterflood and water transfer, and other long-distance or high-pressure injection and transfer duties.

Tundra focuses on front-end engineering, pump specification, and package design, working with trusted OEMs and fabricators to deliver complete pump systems that align with client standards and operating requirements. Our role is to ensure the right technology, configuration, and materials are selected so that the final package integrates smoothly into your facility design and operating strategy.