Integrity Management

Tundra Engineering offers integrity management analysis of specific situations or complete integrity programs for our clients. We utilize state-of-the-art cloud based systems to collaborate with our clients on all items. We offer the most efficient and cost effective solution in the market.

Tundra’s Asset Integrity Services team provides a range of specialized services and technologies that allow facility owners and operators to maintain and improve the safety, reliability, regulatory compliance and efficiency of their assets.

Our services include engineering and inspection of all surface facilities, pressure equipment, tanks and full turnarounds. In addition, we have an in-house data management team which manages our database and program management services.

- Chief inspector services

- Facility Program and Integrity Management

- Integrity Manual Development

- ABSA Qualified Program (AQP) development and training

- Asset Integrity Projects

- Asset Integrity Programs

- Program implementation

- Internal Corrosion

- External Corrosion

- Engineering and Design

- Regulatory and 3rd party audit support

- Safety Loss Management System (SMLS)

- Management of Change (MOC) Program

- Pipeline Operating and Maintenance Manual (POMM)

- Leak Detection Strategy

- Cathodic Protect Design

- Pipeline Integrity Engineering

- Corrosion Services

- Online Reporting

- Pipeline Analysis

- Non-conformance tracking with recommended task lists

- Facility engineering assessments

- Risk based inspections (RBIs)

- Maintenance recommendations and development of future inspection intervals

- Repair engineering and fitness for service

- Automated field inspection forms

- Pressure Equipment Integrity Manual (PEIM)

- Pipeline Risk Assessments

- Weld Overlay and Metal Cladding Design

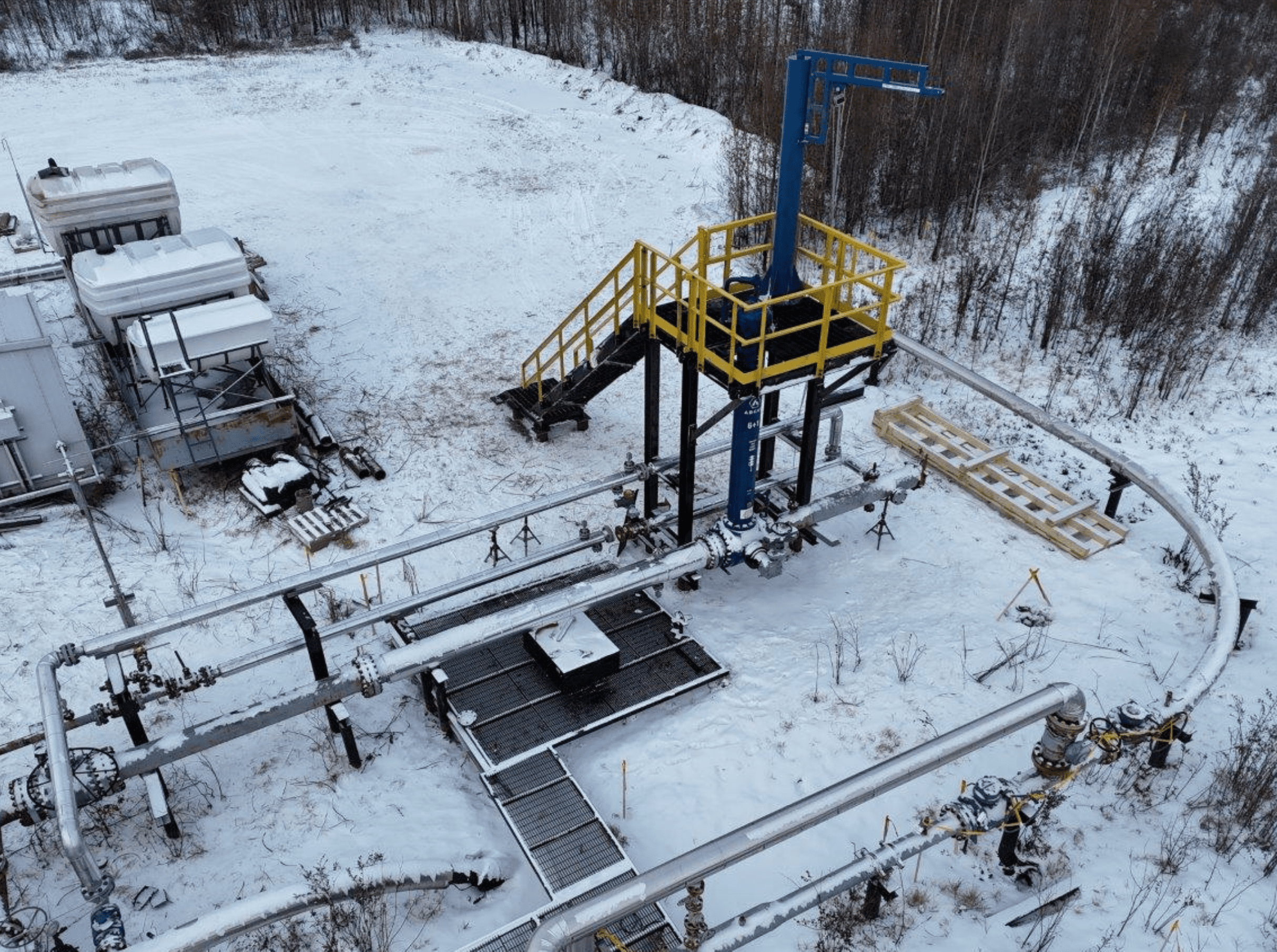

A Tundra auto pig launching system for northern Canada in Winter 2024.